Clean Futures Case Study

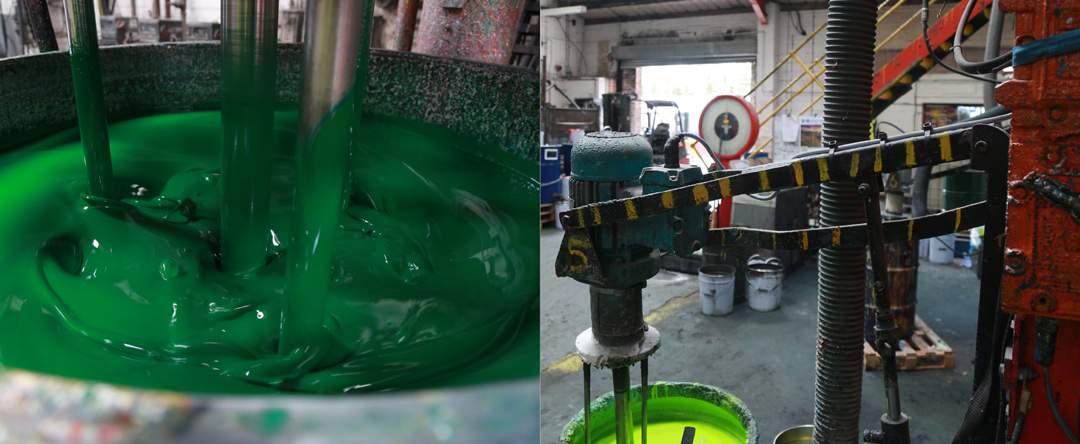

Established in 1903, Thomas Howse is an independent, family-owned manufacturer of industrial paints and powder coatings. The West Midlands business (which currently employs 49 people) was acquired by the Sheibani Group in 2020.

Despite ambitious growth plans, its manual, paper-based approach to sales, marketing, inventory management, and the manufacturing process had led to inefficiencies which needed to be addressed.

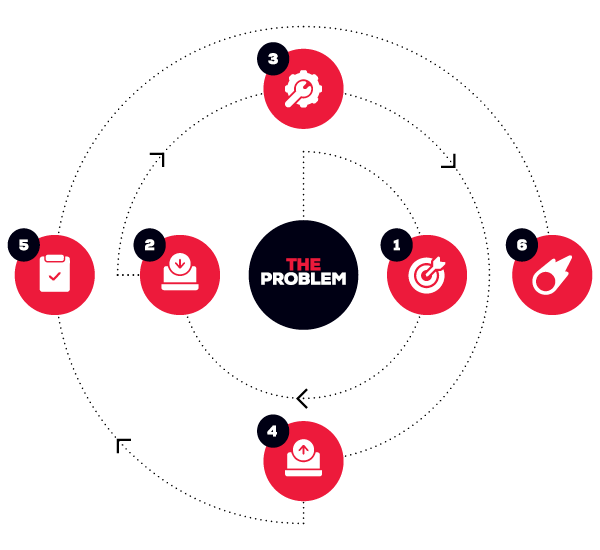

OBJECTIVES

Thomas Howse was keen to identify the inefficiencies in its current processes and establish how it could address them with digital solutions. Its overall objective was to increase efficiency and productivity, allowing for future growth.

Inputs

BCIMO provided a 12-hour ‘Process Improvement’ intervention via its SME Support Programme, a scheme funded by European Regional Development Funding (ERDF).

This was delivered by BCIMO in collaboration with a digital expert.

Activities

A comprehensive audit of the sales, marketing, and manufacturing processes at Thomas Howse was undertaken. This captured how enquiries and orders were processed, inventory managed, manufacturing planned, and products dispatched.

A number of areas for improvement were identified. The business’s paper-based system made it difficult for staff to log customer data, or to establish whether they had sufficient stock or raw materials to fulfil an order. This had an impact on production scheduling in its manufacturing department, which was also unable to collect metrics on overall efficiency.

Outputs

The findings of the audit, together with recommendations for improvement, were presented to General Manager, Garry Plant. It was proposed that Thomas Howse would benefit from either an MRP (Manufacturing Resource Planning) or ERP (Efficiency Resource Planning) system and a referral was made to Made Smarter for further support.

Outcomes

Once implemented with support from Made Smarter, the MRP or ERP system is expected to deliver a rapid return on investment, leading to minimum efficiencies of 15 – 20%. It will also capture valuable data in real-time. This, in turn, will benefit both the business and its customer base.

Long-term impacts

In the longer term, the new digital system will enable Thomas Howse to increase both efficiency and productivity, leading to sustainable, profitable growth. It will also help the business to become paperless and reduce wastage, bolstering its carbon reduction efforts.

The insights BCIMO’s digital expert provided were invaluable, and will undoubtedly lead to future efficiencies. We are looking forward to embarking on the next stage of the process.

– Garry Plant, Thomas Howse

BCIMO is a not-for-profit Research and Technology Organisation (RTO) and operator of the Very Light Rail National Innovation Centre (VLRNIC), a unique, world-class centre for rail innovation based in Dudley in the West Midlands.

Google Map Location: BCIMO

what3words Address: ///shades.glue.tile

Sat Nav: DY1 4AL

Postal Address: BCIMO, Very Light Rail National Innovation Centre, Zoological Drive, Dudley. DY1 4AW

Email: info@bcimo.co.uk

Phone: 07769 586893